A while back, we were in search of a CnC machine (Computer Numerical Control machine) that is used for metal and other various materials.

Before the machine, we didn’t have a very efficient way to make parts for our robots in our own shop. This resulted in us finding very inventive ways to make parts: we’d get crafty, we’d lean on sponsors (like IMP), and occasionally our robot friends would make or cut parts for us (thanks, y’all)! Integrated Metal Products (IMP) knew that we were looking for a machine when they were buying their own, and very generously helped us find and purchase one for our shop! We settled on a HAAS VF-0E CnC vertical milling machine, an older model with some charm to it.

As expected, when the HAAS first arrived it was in need of some TLC. We set it up & were ready to start making some parts but it was unresponsive, so we did some troubleshooting and found a few main things that may have been causing the machine to misbehave. First, several wires had come loose during transport; this was the easy fix. Next, the HAAS needed a replacement on its quick exhaust valve, as the old one was leaking and wouldn’t hold the correct pressure. With our older model, we knew it would be difficult to find a valve that would fit our machine. Finally, the machine needed an intensive cleaning. It took a few weeks and a lot of elbow grease to find the main issues with the machine, but after we located them, we got to work. Many updates, tweaks, and tests later, it was finally working properly!

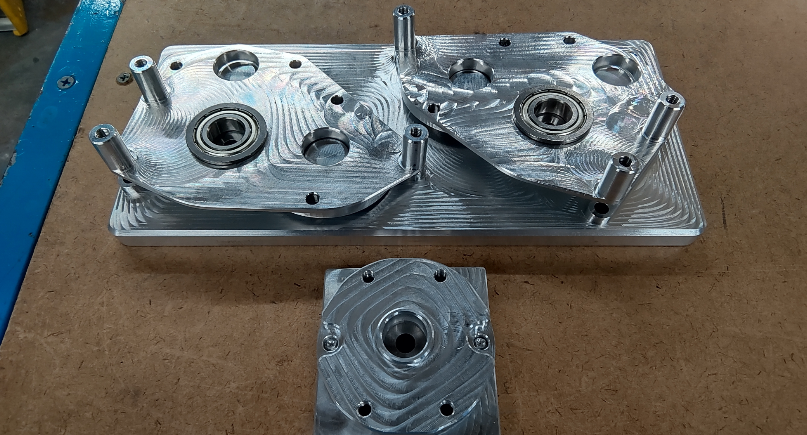

It was also finally ready for tooling! We then made it to a key milestone: it produced its first chips. The HAAS modifies a workpiece through the removal of a material. The material that is being extracted is a chip. With this accomplished, we were able to finally say that we could begin to use the machine without any long-term issues ahead.

After many weeks of trying to get this machine to work properly, we didn’t give up, and now everything on the HAAS is completely operational! We’re looking forward to using this machine to make many parts, especially considering the new HAAS speeds up our iterating time (because we can test a part, make changes to the design, or cut a new one).

Lastly, we would like to again thank IMP for alerting us about the machine and helping us purchase it at a price we could afford!

Leave a Reply

You must be logged in to post a comment.